Throttle Cable Adjustment

Synchronization of the oil pump and carburetors is extremely important

to assure adequate engine lubrication and peak performance.

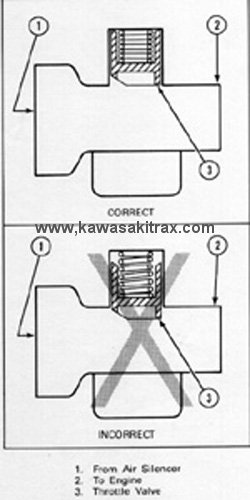

1) Loosen idle stop screws so that both throttle valves bottom out in the

carburetor bores.

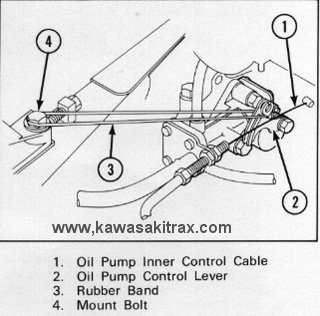

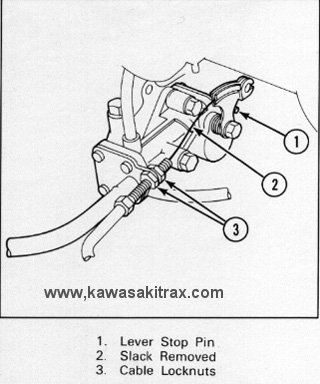

2) Push oil pump lever forward until it contacts the stop pin; this insures

that the oil pump is at the dead idle position. (see figure 2-53)

3) Adjust throttle cable on the LH carburetor so that all of the slack

is removed. The throttle valve should begin to raise as soon as the throttle

lever on the handlebar is moved.

4) Loosen the locknuts on the oil pump cable, while holding the oil pump

lever against the stop pin, removing all of the cable slack. Adjustment is

correct when the lever on the oil pump and the throttle valve on the LH

carburetor move simultaneously as the throttle control lever is activated.

5) Adjust RH carburetor throttle cable so that oil pump lever and both throttle

valves move simultaneously as the throttle control lever is activated.

6) Perform any remaining carburetor adjustments as required.

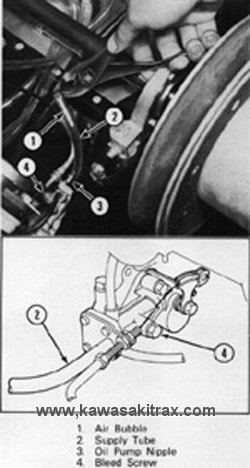

After performing maintenance on the oil injection system components or filling

the oil tank for the first time OR the oil tank has run empty, follow the procedures

under "Oil Injection System Bleeding" to insure adequate engine lubrication.

CAUTION: Failure to bleed trapped air from the oil injection system will result in severe engine damage.